HOME>>Product Description(Filler Powder/Filler Masterbatch/Additives)>>Talc-based Pellet

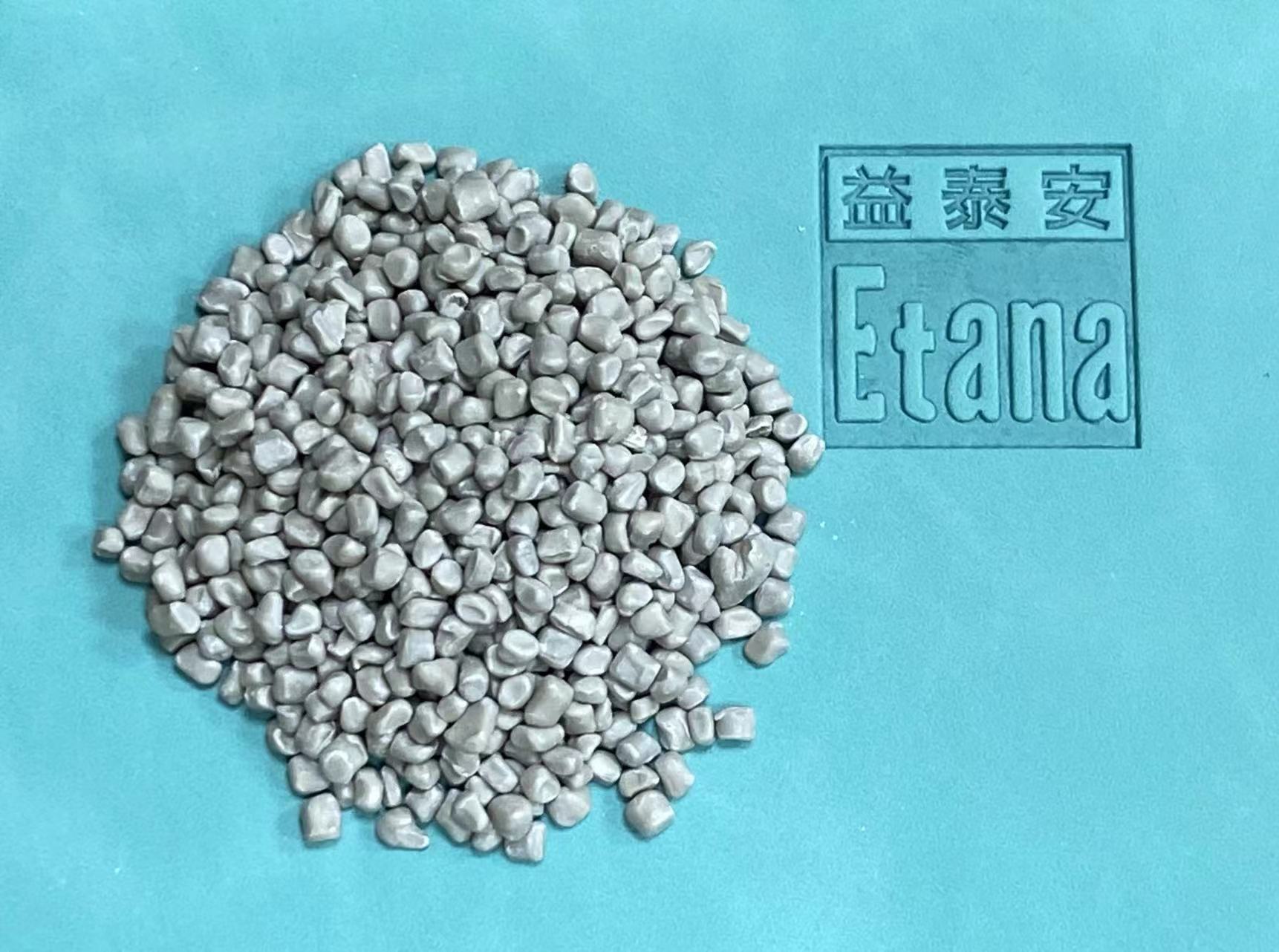

Talc-based Pellet

Description

Talc Filler Masterbatch is a high-performance plastic filler made from ultra-fine talc powder, polymer carriers (such as PP or PE), and functional additives through high-temperature compounding and pelletizing. It is widely used to enhance the performance of plastics, rubber, and other resin-based materials. With excellent processability and functional properties, it plays a critical role across various industries.

Features

Excellent physical properties: Talc has a layered structure, and this flake form can be evenly dispersed in the plastic matrix, thereby improving the rigidity, heat resistance, and dimensional stability of the material.

Improved Processability: Due to the low hardness of talc, it reduces wear on equipment during processing and improves the flowability of the material, thereby enhancing production efficiency.

Enhanced Thermal Stability: The addition of talc filler masterbatch increases the heat deflection temperature of plastics, allowing the material to maintain stability under high-temperature stress. This is particularly important for applications that require high-temperature performance.

Cost-effectiveness: Talc masterbatch is relatively inexpensive and, when used as a filler, can effectively reduce the production cost of plastic products while enhancing their performance.

Environmental Benefits: It completely resolves the environmental and health issues caused by the addition of powder.

Applications

Plastic Industry: It is widely used as a filler and reinforcing agent in automotive parts, home appliance shells, plastic containers, and more, enhancing the rigidity, heat resistance, and dimensional stability of plastic products, while reducing production costs and maintaining excellent mechanical properties.

Packaging Industry: Applied to films and containers, such as those used in food and pharmaceutical packaging, it enhances the stiffness and barrier properties of the films, while improving tear resistance and printability.

Wires and cables: As a filler in insulating materials, it improves heat resistance and mechanical strength, enhances flame retardancy and dimensional stability, and helps reduce material shrinkage and deformation.

Building Materials: Used in PVC door and window profiles, pipes, and more, it improves weather resistance and impact strength, enhances dimensional stability and surface quality, and reduces the coefficient of thermal expansion.

Home Appliance Shells: Applied to the outer shells of products such as TVs, air conditioners, and washing machines, it provides excellent surface gloss and rigidity, improves scratch resistance and heat deflection temperature, and supports subsequent spraying and dive processes.

Agricultural Films: Used in greenhouse films, mulch films, and other agricultural applications, it enhances the mechanical strength and weather resistance of the films, improves UV resistance, regulates light diffusion, and promotes plant growth.