HOME>>Product Description(Filler Powder/Filler Masterbatch/Additives)>>BaSO4 Masterbatch

BaSO4 Masterbatch

Description

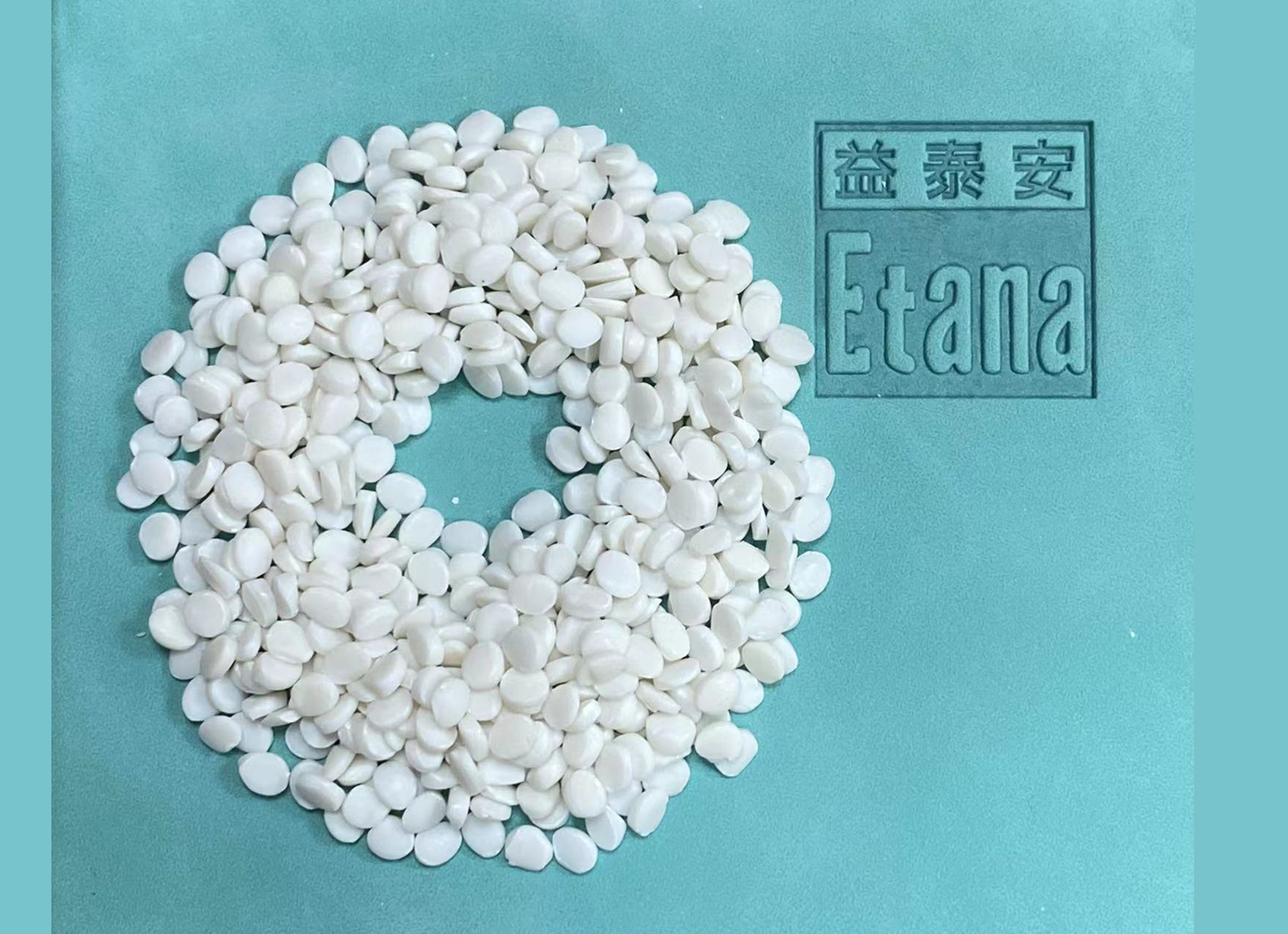

Barium sulfate masterbatch is a functional plastic masterbatch composed mainly of high-concentration, high-whiteness ultra-fine barium sulfate powder (BaSO₄), combined with a polyolefin carrier (such as polyethylene, PE) and other processing additives. It is manufactured through high-temperature compounding and extrusion pelletizing.

The key advantage of barium sulfate masterbatch is that it is added in a pelletized form, which avoids issues such as dust pollution and uneven dispersion caused by the direct use of barium sulfate powder, while also improving production efficiency and product performance.

Features

High transparency: Nano-sized barium sulfate is used to reduce light scattering, helping maintain high light transmittance in the plastic matrix.

High gloss: The nano-crystalline barium sulfate features a spherical structure and a high L-brightness value of up to 99.5—significantly higher than the typical surface L-value range of 40–90 for plastics—resulting in an ultra-glossy finish and a more visually appealing product.

Excellent dispersibility: Advanced synthesis and nano-level surface treatment eliminate particle agglomeration, ensuring consistent quality and uniform appearance in end products.

Enhanced mechanical properties: The incorporated nano-powder has a narrow and uniform particle size distribution, along with specialized surface treatment and low oil absorption, effectively enhancing the tensile strength, reinforcement, and overall mechanical performance of the final product.

Excellent weather resistance: Offers resistance to acids, alkalis, corrosion, oxidation, and UV radiation, helping inhibit product aging and extend service life.

Good printability: Capable of reducing the surface electrical intensity of film products, thereby improving printing quality and efficiency.

Low wear property: Features a neutral pH value and relatively low Mohs hardness, which will not cause wear or corrosion to parts such as screws or die heads.

Applications

Blown film products: Barium sulfate masterbatch is commonly used in LDPE, LLDPE, and HDPE blown film processes. It significantly enhances the film’s transparency, gloss, and density, while also increasing rigidity and durability. This makes it suitable for applications such as food packaging, shopping bags, garbage bags, and agricultural mulch films.

Injection molding: In injection molding processes, barium sulfate masterbatch is used to manufacture household items, toys, furniture, and construction materials. It enhances surface smoothness and hardness, improves acid and alkali resistance as well as impact resistance, and increase the weight of the product.

Extrusion molding: Barium sulfate masterbatch is widely used in plastic sheets, pipes, and other extrusion-molded products. It helps reduce shrinkage, improve dimensional stability, and enhance the mechanical properties of the products.

Extruded sheets and films: In extrusion processes, barium sulfate masterbatch can increase the density and rigidity of sheets or films, while improving optical properties such as transparency and gloss. This makes it suitable for high-end decorative materials or packaging applications.

Construction and home appliance shells: Barium sulfate masterbatch enhances the rigidity and noise-reduction performance of construction materials (such as drainage pipes) and home appliance shells (such as speaker enclosures), while also increasing their weight and tactile feel.