HOME>>Product Description(Filler Powder/Filler Masterbatch/Additives)>>Mg(OH)2-based Pellet

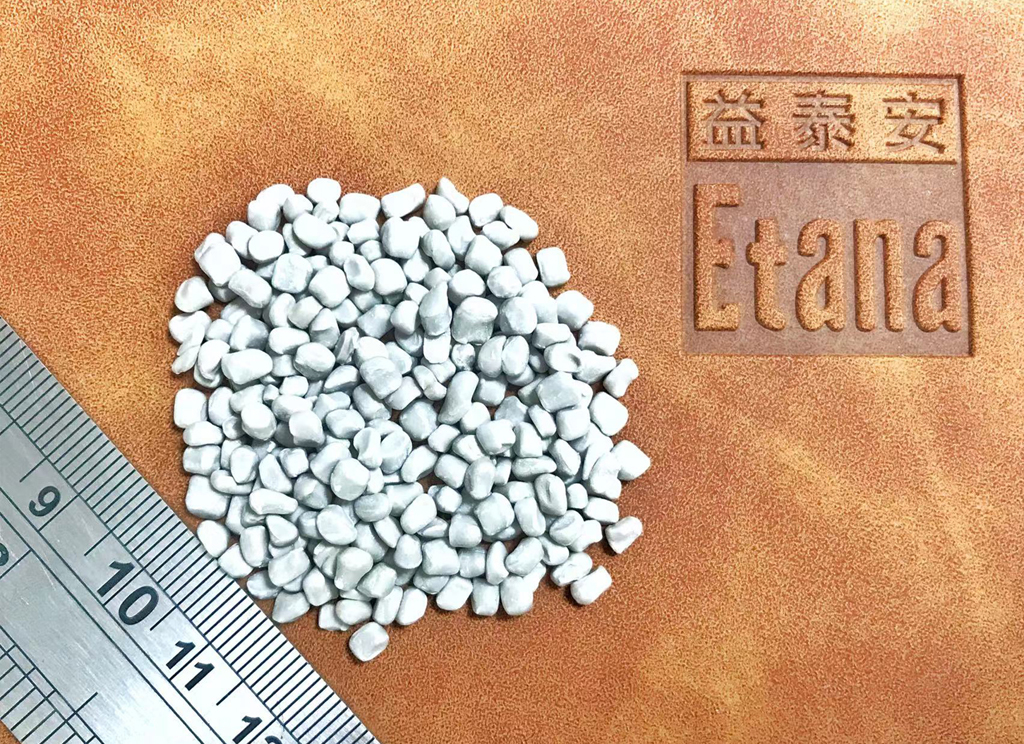

Mg(OH)2-based Pellet

Description

Magnesium Hydroxide Masterbatch is an environmentally friendly, halogen-free flame retardant masterbatch formulated with magnesium hydroxide (Mg(OH)₂) as the main functional filler. It is produced by melt compounding high-purity magnesium hydroxide powder with a carrier resin under high temperature. As a halogen-free and environmentally friendly flame retardant, magnesium hydroxide decomposes endothermically when exposed to heat, releasing water vapor that suppresses combustion and dilutes flammable gases-achieving a dual flame-retardant effect. The masterbatch form effectively solves the problems of poor dispersion and dust associated with traditional powder fillers, making it particularly suitable for plastic products requiring high flame retardancy.

Features

High Flame Retardant Efficiency: As an eco-friendly flame retardant masterbatch, magnesium hydroxide decomposes at around 340°C. The endothermic reaction lowers the material's surface temperature, while the released water vapor effectively suppresses combustion.

Eco-Friendly and Non-Toxic: As an inorganic compound, magnesium hydroxide does not produce toxic or corrosive gases during combustion, meeting environmental and safety standards.

Smoke Suppression Performance: Magnesium hydroxide produces significantly less smoke during combustion compared to traditional flame retardants such as aluminum hydroxide or brominated compounds.

High Temperature Resistance and Stability: Suitable for processing engineering plastics with relatively high temperatures; however, excessive heat may cause decomposition.

Filler Modification: Enhances material rigidity, but excessive addition may reduce toughness and flowability, and needs to be optimized with a compatibilizer.

Applications

Wire and Cable: Halogen-free flame-retardant wire coatings that meet fire safety requirements for construction and automotive wiring harnesses.

Electronics and Electrical Appliances: Components requiring high flame retardancy, such as socket housings and battery separators.

Building Materials and Transportation: Fire-resistant coatings, flame-retardant panels for subways, and automotive interior parts such as instrument panel backings.

New Energy field: Lithium battery casings or thermal insulation materials designed to prevent thermal runaway risks.

Packaging Films: Flame-retardant films for specialized applications such as military and aerospace packaging.

Rubber Products: Used as a flame-retardant filler in the rubber industry to enhance fire resistance.